![]() Deutsch

Deutsch

![]() Espanol

Espanol

![]() Francais

Francais

![]() Italiano

Italiano

![]() Portugues

Portugues

![]() Japanese

Japanese

![]() Korean

Korean

![]() Arabic

Arabic

![]() Russian

Russian

![]() Deutsch

Deutsch

![]() Espanol

Espanol

![]() Francais

Francais

![]() Italiano

Italiano

![]() Portugues

Portugues

![]() Japanese

Japanese

![]() Korean

Korean

![]() Arabic

Arabic

![]() Russian

Russian

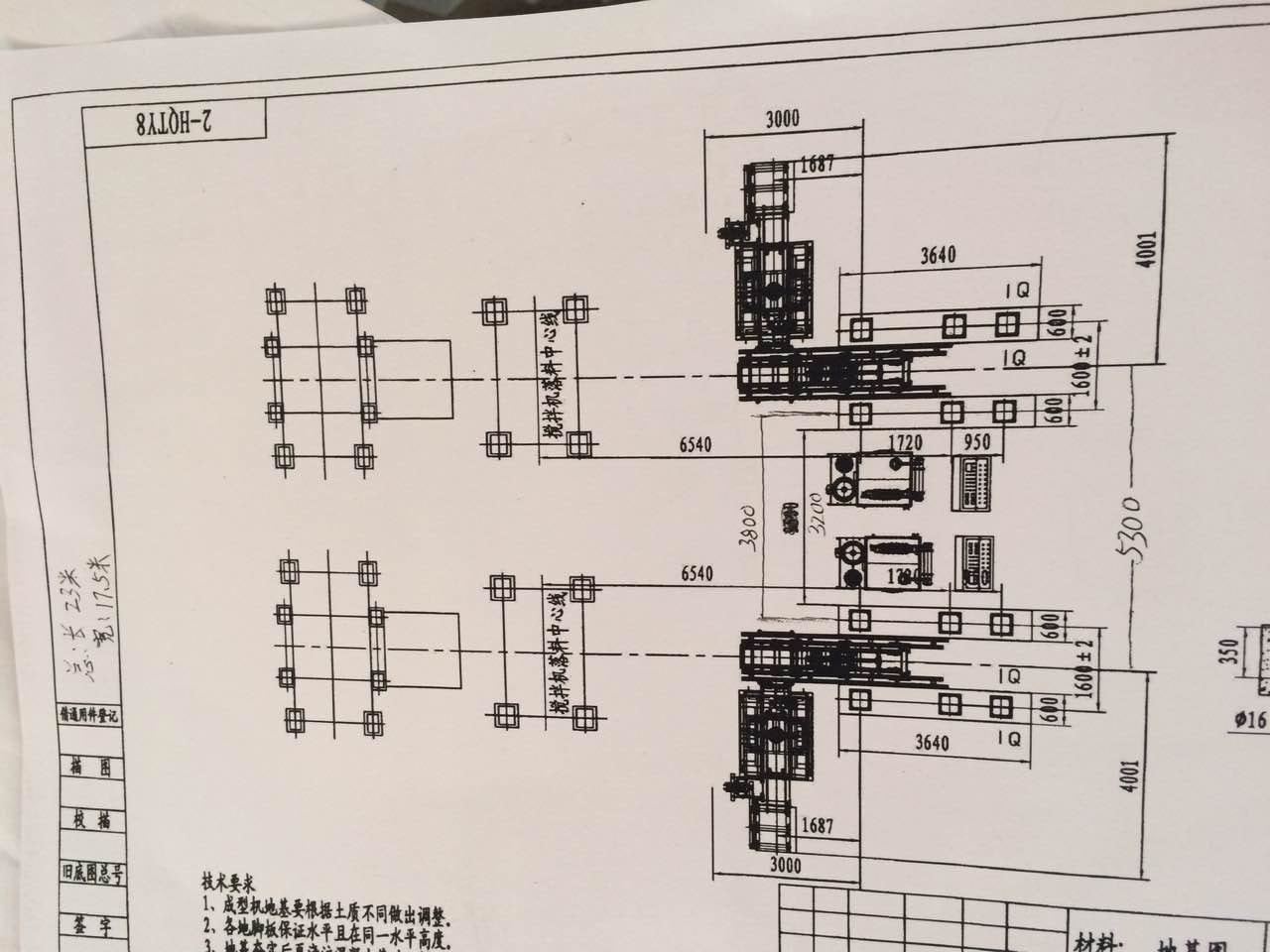

What are the requirements for site circuit of concrete brick making machine before installation and commissioning

Circuit requirements:

It shall have a power supply of no less than 50-80kw with a voltage of 380V 50Hz;

3-phase 4-wire is arranged in the plant, and 50-60mm2 copper core wire is recommended for cable;

It is recommended to use 25mm2 copper core wire from the wires arranged in the plant to the power line of the host, and more than 100A for air switch;

It is recommended to use 25 mm2 copper core wire from the wires arranged in the plant to the power line of the mixer, and more than 100A for the air switch;

Used oil: original barrel of "Great Wall" brand grinding hydraulic oil: about 680kg (4 barrels) in cold areas 46#, tropical areas 68#.

Brick connecting plate (bamboo glue supporting plate / PVC supporting plate): the number of brick connecting supporting plates with the following specifications shall be selected according to the machine model.

QT3-25 680 × five hundred and thirty × 25mm, at least 1000 for standby and 2000 for normal

QT4-25 880 × five hundred and fifty × 25mm, at least 1000 for standby and 2000 for normal

QT5-15 1100 × five hundred and sixty × 25 / 30mm, at least 1000 pieces shall be prepared, and 2000 pieces shall be normal

QT6-15 940 × eight hundred and thirty × 25mm, at least 1000 for standby and 2000 for normal

QT6-21 940 × eight hundred and thirty × 25mm, at least 1000 for standby and 2000 for normal

QT8-15 940 × eight hundred and sixty × 25mm, at least 1000 for standby and 2000 for normal

QT9-15 1350 × seven hundred and twenty × At least 1000 pieces for 30mm and 2000 pieces for normal use

QT10-15 1200 × eight hundred and sixty × At least 1000 pieces for 30mm and 2000 pieces for normal use

QT12-18 1350 × eight hundred and sixty × At least 1000 pieces for 30mm and 2000 pieces for normal use

All supporting equipment (batching machine, mixer, etc.) shall be in place if purchased by ourselves.

A water tank or plastic bucket shall be set beside the mixer, with a minimum water capacity of more than 2 tons for the cooling water of the mixer and oil tank.

The ground cement and relevant foundation positions of the factory workshop must be hardened

Contact: Kaner

Phone: +86 15394434019

E-mail: info@onnoh.com

Add: Dongmen Industrial District,Fengzhou Town,Quanzhou ,Fujian .CHINA