![]() Deutsch

Deutsch

![]() Espanol

Espanol

![]() Francais

Francais

![]() Italiano

Italiano

![]() Portugues

Portugues

![]() Japanese

Japanese

![]() Korean

Korean

![]() Arabic

Arabic

![]() Russian

Russian

![]() Deutsch

Deutsch

![]() Espanol

Espanol

![]() Francais

Francais

![]() Italiano

Italiano

![]() Portugues

Portugues

![]() Japanese

Japanese

![]() Korean

Korean

![]() Arabic

Arabic

![]() Russian

Russian

There are often places that customers are not clear about. What is the after-sales installation process that customers receive after ordering a concrete brick making machine? Today, the editor of ONNOH Machinery will introduce it to you.

First of all, the after-sales engineer of ONNOH Machinery Company will travel to the customer's site, make local planning according to the actual situation of the customer's site, and mark the location of the equipment to be installed.

Carry out the construction of pre-embedded iron on the concrete foundation for the position of the scribed line to prepare for the later installation of the production line.

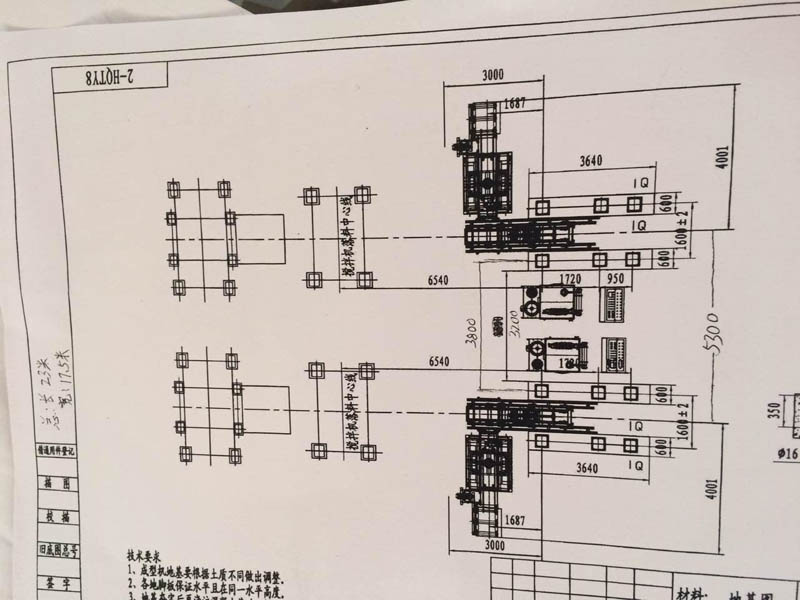

The company will plan a layout drawing of the embedded parts of the production line according to the customized model and the actual site.

After the foundation of the production line is completed, the ground and floor of the site shall be hardened with concrete. The next work is the specific after-sales installation process from the technical engineer to the site.

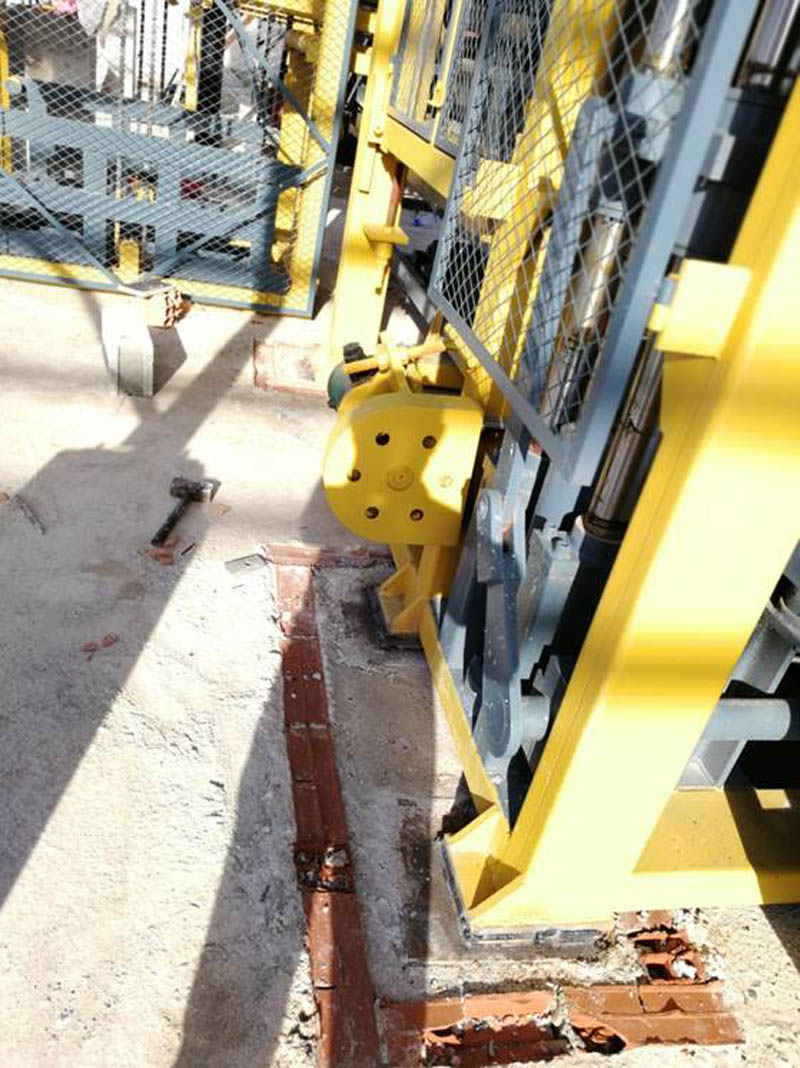

When you first arrive at the construction site, it is necessary to confirm whether the basic pre-embedded iron is well prepared, and the pre-embedded iron should be as level as possible.

Assemble the conveyor belt, batching bin and powder tank in advance for hoisting.

When the block making machine equipment is hoisted and placed, it should be placed in order from the position of the batching bin to the front. The order of placement is: batching warehouse, mixer, brick machine host, plate feeder, conveyor belt, brick machine, brick stacker. Side pallet trigger. Powder tank, cement screw, and then connected to mixer lifting track and cement measuring bin. (Warning, pay attention to safety when lifting!)

Before connecting, check whether the fuel tank has accumulated water in the tank due to transportation or parking in the open air. If it is found, it should be drained in time, and the side inspection port should be opened to clean it with a clean rag. When connecting, search for the corresponding oil nozzles and connect the oil pipes in turn according to the order of the oil circuits. The distance between the oil tank and the main engine should be slightly higher than the ground to avoid friction during work.

No. 46-68 anti-wear hydraulic oil (subject to type 6 machine) 3 barrels * 200 liters. Gear oil 2 barrels * 46 liters. Lubricating grease 1 barrel * 46 liters.

The main power line 3*35+16 square copper core wire is equipped with 150-200A air switch, and then divided into two 3*16 square wires to enter the host respectively, and the mixer control cabinet is also equipped with two 100A air switches. The board machine can use 4*4 square line. Cement spiral 4*4 square line. The required length is measured according to the actual site. (If there is a change in the power of the motor, also adjust the specifications of the power cord according to the actual situation)

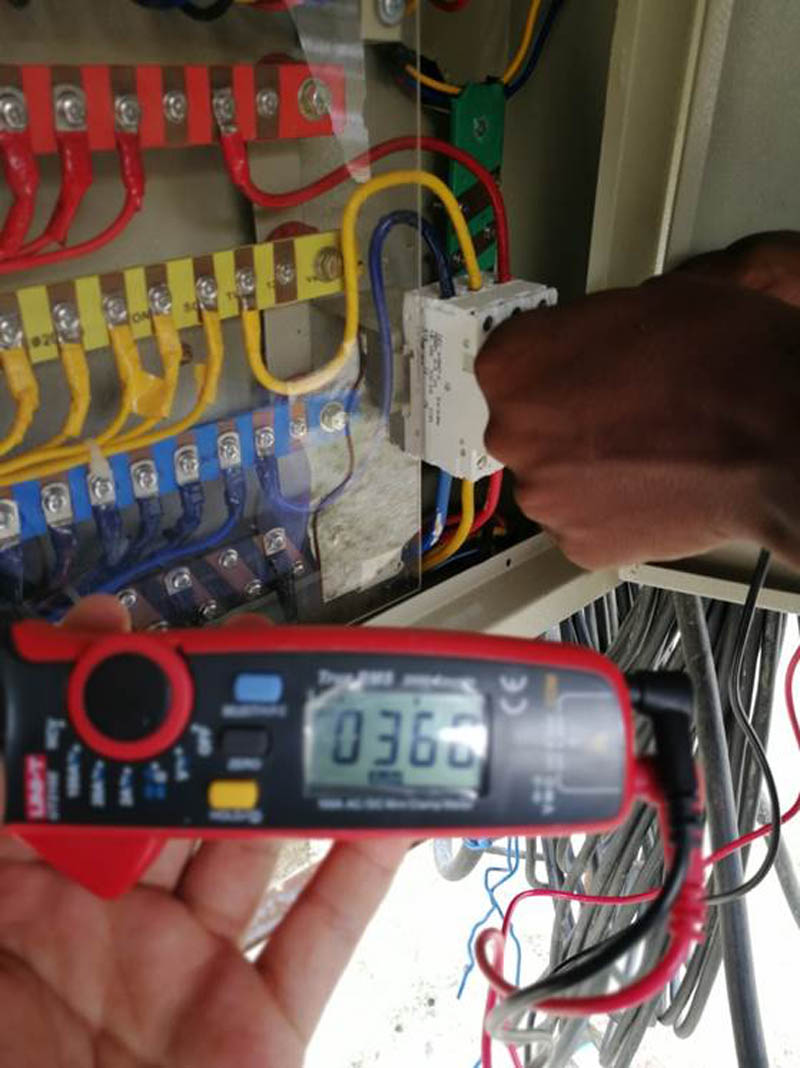

After turning on the power supply, check the power supply voltage in the power cabinet and turn off the power supply of the equipment control box. (The domestic voltage is subject to three-phase 380V and two-phase 220V, and the voltage should not exceed ±7%)

Connect the equipment lines, and try to place the wire grooves as much as possible to avoid faults such as poor contact caused by stepping on them in the future.

The short circuit of the electronic scale sensor needs to be connected with the shielding net to avoid interference when the equipment is running.

After the power is turned on, check and test the motors one by one. At this time, it must be carried out in the debugging state to check whether the motor is abnormal and whether the forward and reverse directions are correct.

Debug step sequence:

(1) Put down the lifting bucket and adjust the discharge distance between the hopper and the aggregate measurement.

(2) Arrange the main machine, install the conveyor belt, and install the unloading bin, so that there is no deviation between the discharge port of the mixer and the four sides of the bin.

(3) Precautions for cement measurement, the welding of the opening and diameter of the cement silo and the spiral chain interface, it is necessary to pass the ground wire over the electronic scale sensor, so as to prevent the electric welding current from passing through the sensor and causing damage to it.

(4) After aligning the main machine, align the plate feeder and the brick machine to the vibrating table, and place a pallet on the vibrating table and the top of the two for leveling. The front and rear need to be kept level.

(5) For the placement position of the stacker, the pallet needs to be at the stop position of the stacker as a reference, and the placement is adjusted by the lifting position of the hook of the stacker.

Flatten and fix all parts of the equipment with electric welding and expansion screws.

Prepare the small water pump and water pipes

After the final brick machine production line is installed

Contact: Kaner

Phone: +86 15394434019

E-mail: info@onnoh.com

Add: Dongmen Industrial District,Fengzhou Town,Quanzhou ,Fujian .CHINA