![]() Deutsch

Deutsch

![]() Espanol

Espanol

![]() Francais

Francais

![]() Italiano

Italiano

![]() Portugues

Portugues

![]() Japanese

Japanese

![]() Korean

Korean

![]() Arabic

Arabic

![]() Russian

Russian

![]() Deutsch

Deutsch

![]() Espanol

Espanol

![]() Francais

Francais

![]() Italiano

Italiano

![]() Portugues

Portugues

![]() Japanese

Japanese

![]() Korean

Korean

![]() Arabic

Arabic

![]() Russian

Russian

Onnoh QT4-15 automatic hollow block machine adopts color touch screen and PLC control, equipped with data input and output device, and the distribution system adopts forced arch breaking device to adapt to the distribution of mold cavity of different products, with uniform distribution and no dead corner. With the characteristics of high efficiency and energy saving, large output, good quality and small investment, it is the first choice of cement brick making equipment for small and medium-sized brick factories.

Onnoh QT4-15 automatic wonton brick machine can cooperate with automatic assembly line operation and save a lot of labor, so as to ensure low investment and high output. Changing molds can produce wall tiles and floor tiles of different specifications. Production raw materials: crushed stone powder, sand, stone, cement, a large amount of fly ash, slag, industrial waste, slag, construction waste, solid waste, etc. can be added as raw materials.

QT4-15 BLOCK MACHINE TECHNICAL PARAMETER:

QT4-15 Technical Specifications | |

Vibration trequency | 3800-4500(r/min) |

Total weight | 8(T) |

Machine Size | 9150*3100*2600(mm) |

Total power | 26.7(kw) |

Cycle time | 12-20(s) |

Rated pressure | 25MPa |

68Vibration force | 68KN |

Pallet site | 980*560*20(mm) |

Vibration type | Hydraulic vibration |

Stacking machine power | 3.0KW |

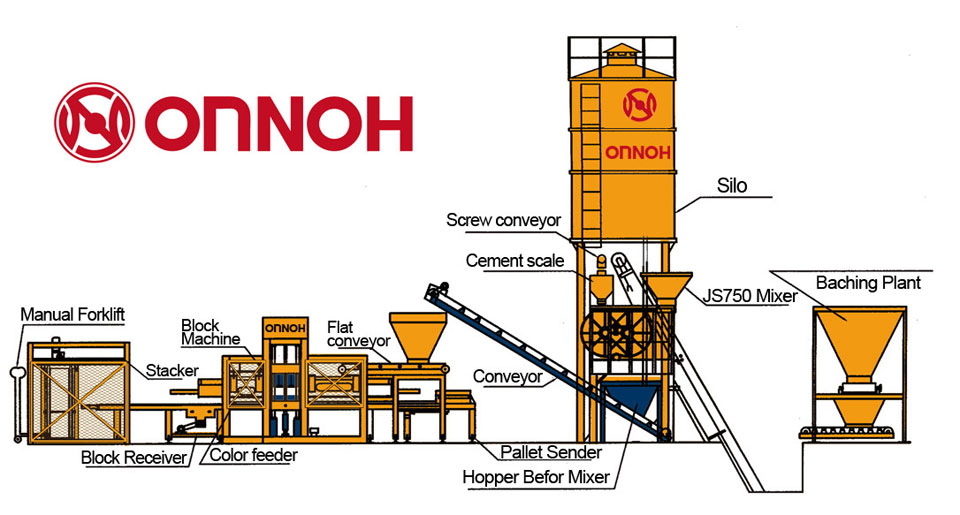

QT4-15 block making machine BASIC PRODUCE LINE:

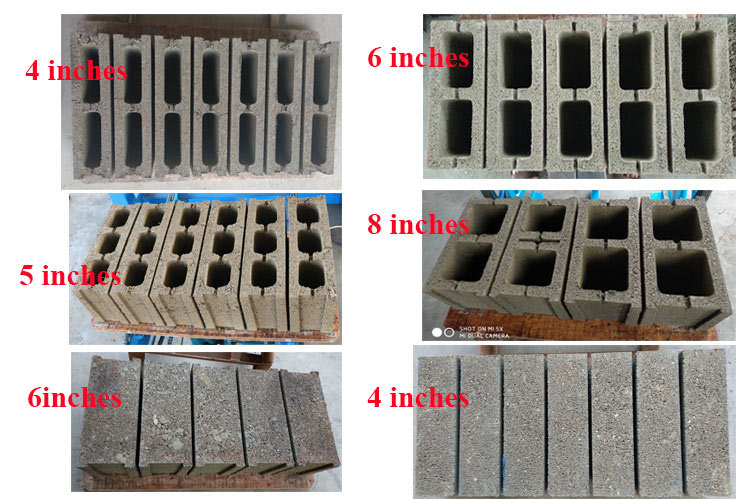

Block Machine can make many kinds of blocks only by changing the molds easily

Item | Specification size | Quantity per mold | Cycle molding | Per hour |

Hollow brick | 390*190*190 (mm) | 4pcs/mold | 15~20s | 720~960pcs/h |

Porous brick | 240*115*90 (mm) | 14pcs/mold | 15~20s | 2520~3360pcs/h |

Standard brick | 240*115*53 (mm) | 28pcs/mold | 15~17s | 5930~6720pcs/h |

Technical features of QT4-15 block machine:

1. The electrical system adopts imported color touch screen and PLC control, equipped with data input and output device, and the control system includes safety logic control and fault diagnosis system.

2. Imported hydraulic components and seals adopt high dynamic performance proportional valve, which can adjust oil volume and pressure according to different working requirements to accurately control the action of key components.

3. The machine adopts table vibration pressure forming and reciprocating guiding feeding device. It has the advantages of short forming cycle, high production efficiency, dense block quality, high strength and accurate size.

4. The technology of mechanical, electrical and hydraulic integration is adopted to make each cycle process of equipment operation consistent, so the stability of formed products is high and the scrap rate is low.

5. One machine is multi-purpose. By changing the mold, it can produce cement products such as porous brick, hollow block, kerb, pavement brick, grass tree brick, slope protection brick and so on.

6. With fabric device, it can produce color road tiles and other products.

Client case and block samples:

![]()

Contact: Kaner

Phone: +86 15394434019

E-mail: info@onnoh.com

Add: Dongmen Industrial District,Fengzhou Town,Quanzhou ,Fujian .CHINA