![]() Deutsch

Deutsch

![]() Espanol

Espanol

![]() Francais

Francais

![]() Italiano

Italiano

![]() Portugues

Portugues

![]() Japanese

Japanese

![]() Korean

Korean

![]() Arabic

Arabic

![]() Russian

Russian

![]() Deutsch

Deutsch

![]() Espanol

Espanol

![]() Francais

Francais

![]() Italiano

Italiano

![]() Portugues

Portugues

![]() Japanese

Japanese

![]() Korean

Korean

![]() Arabic

Arabic

![]() Russian

Russian

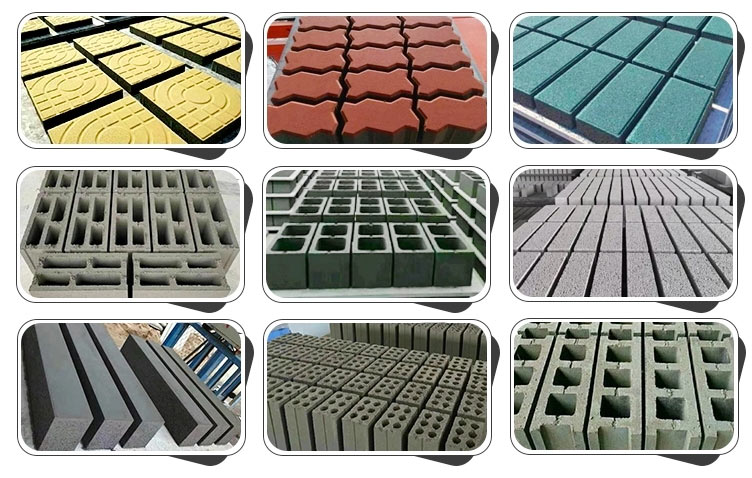

QT9-15 concrete block machine production line can produce hollow blocks, solid bricks, porous blocks and some pavers of different sizes.With frequency conversion technology, the whole equipment can be analyzed and personalized designed according to the actual situation of users to provide the most appropriate equipment scheme. Provide customers with site planning, on-site commissioning, professional training, lifelong technical services, spare parts supply, etc. free of charge.

QT9-15 automatic block machine equipment adopts advanced vibration technology, and the automatic feeding forming system uses crutch arm to avoid damaging the green block when lifting the mold base. Advanced vibration technology and different vibration modes are adopted for feeding and forming to ensure the high quality of feeding and forming.

This machine is suitable for large and medium-sized investment customers.

QT9-15 Technical speciafications

Vibration Frequency | 3800-4500r/min |

Main machine weigh | 14500KG |

Dimension | 9800*4050*2800mm |

Capacity | 48.9KW |

Cycle Time | 15-23(S) |

Rated pressure | 31.5mpa |

Vibration force | 105KN |

Pallet size | 1350*680mm |

QT9-15 Block Machine Technical Parameter

Item | Specification(mm)(L*W*H) | Quantity per hour |

Concrete block | 390*190*190 | 1458-1620 |

Solid block | 240*115*53 | 8100-9000 |

Porous block | 240*115*90 | 4500-5000 |

1. The onnoh automatic brick making machine system can collect and stack the produced concrete bricks. At the same time, it can clean and stack trays.

2. Save 5-6 people and improve production efficiency.

3. As shown in the figure, 360 degree rotating manipulator, stacker, frequency converter and proportional valve control system. Therefore, the stacker can clamp bricks accurately and operate stably.

4. As shown in. Independent intelligent console, using German Siemens PLC component control system and LCD to realize man-machine dialogue.

5. Push and reassemble the brick in a unique way. The brick can be adjusted with the size of a square.

6. German control system and photoelectric switch are used to ensure correct movement of each action.

Contact: Kaner

Phone: +86 15394434019

E-mail: info@onnoh.com

Add: Dongmen Industrial District,Fengzhou Town,Quanzhou ,Fujian .CHINA