![]() Deutsch

Deutsch

![]() Espanol

Espanol

![]() Francais

Francais

![]() Italiano

Italiano

![]() Portugues

Portugues

![]() Japanese

Japanese

![]() Korean

Korean

![]() Arabic

Arabic

![]() Russian

Russian

![]() Deutsch

Deutsch

![]() Espanol

Espanol

![]() Francais

Francais

![]() Italiano

Italiano

![]() Portugues

Portugues

![]() Japanese

Japanese

![]() Korean

Korean

![]() Arabic

Arabic

![]() Russian

Russian

QT15-15 Automatic Hollow Block Making Machine is applied in producing high-strength and fine-quality ordinary concrete blocks,fly ash blocks, waste residue blocks, etc.The blocks produced are featured with high consistency, good capabilities in frost-resistance, permeability-resistance, sound insulation, thermal insulation, heat-preservation property and reliable performance.

QT15-15 Automatic Hollow block making machine:

Specifications of QT15-15 main machine | |

Dimension of host machine | 5800*2400 *2800mm |

Pallet size | 1300x1100mm |

Total power | 150.45kw |

Weight of the host machine | 16ton |

Vibration force | 100KN |

Molding cycle | 15~20S |

Rated pressure | 15~30Mpa |

Material Consumption | 300~340ton/day |

Electric Consumption | 155kw.h/day |

Water Consumption | 15ton/day |

Worker | 4-8workers |

QT15-15 Main Parts Brick Output

Size(L*W*H) | QTY/Mould(pcs) | QTY/Hour(pcs) | QTY/8Hour(pcs) |

400×200×200mm | 15 | 2700 | 21600 |

400x150x200mm | 18 | 3240 | 25920 |

400x100x200mm | 27 | 4860 | 38880 |

240x115x53mm solid | 60 | 14400 | 115200 |

200x100x60mm pave | 55 | 9900 | 79200 |

Siemens motor system is adopted for main machine of brick making machine, and EU standard is adopted for special motor to ensure working stability.

The size of vibration box is increased according to molding area and special brick type. The vibration box with wide area is driven from four directions to ensure the balance of vibration and the effective transmission of vibration force to brick. Compared with vibration system driven by two motors, the vibration efficiency is increased by 30-40%, so as to improve the density and strength of finished brick.

It can effectively reduce the vibration noise, quickly eliminate the high-frequency vibration of the whole machine caused by the residual vibration force, so as to prolong the service life of the machine and the mold, and reduce the noise damage and interference to the operators.

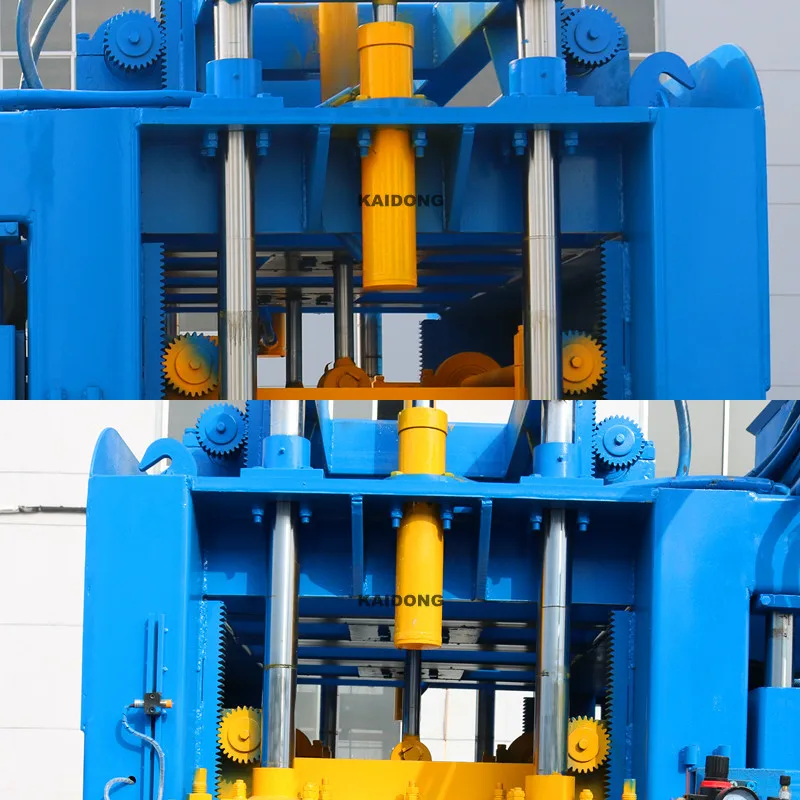

Four synchronous shafts (eight synchronous rack and pinion positioning units) are used for accurate positioning of the upper and lower molds. The gear rack is machined and polished by German and Japanese high-precision machine tools to ensure that the front, rear, left and right sides of the mold are always kept at the same level when the mold body moves up and down, so as to ensure that the height of the cement brick is always consistent. At the same time, the friction coefficient of the upper and lower dies is reduced and the service life of the mould is prolonged.

Adopting the German design concept, the distribution system adopts double crank arm, double synchronous shaft and 4-cylinder high-efficiency and accurate distribution system to ensure the stability of the distribution system and the efficiency of the feeding speed. Ensure the brick production, reduce the maintenance rate of the machine distribution system.

Ensure the stability and long service life of the program.

Ensure the effective input and output of hydraulic system and long service life.

All the moulds are made of the national standard steel (which has reached the European Union standard). After high-precision cutting and high-temperature carburizing heat treatment (900 ℃ high temperature, 200 ℃ tempering), the die hardness reaches 55-63HRC (ordinary steel has only 25-30HRC hardness).

According to the machine forming area (mold area), choose 2 to 4 axis thickening and lengthening vibration box to ensure the compactness of finished brick

The main control box adopts French Schneider, German Siemens and or Switzerland ABB switch to ensure working stability and service life.

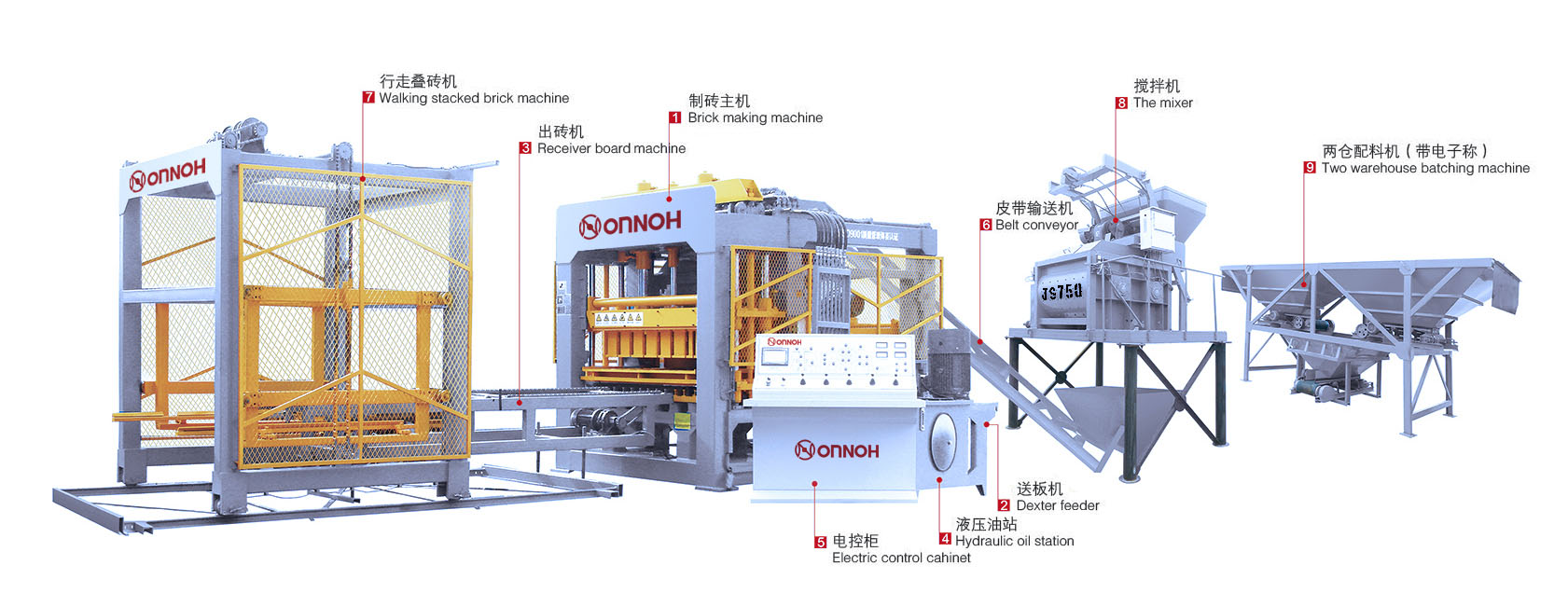

Fully automatic line as following:

1. Automatic weighing system

2. Twin shaft compulsory mixer

3. Mitsubishi PLC, Touch screen control unit

4. Hydraulic proportional relief valve automatically adjust the oil flow and speed

5. Heave duty frame of steel structure for heave working

6. Mould heat treatment with wire cutting

7. One production line can make all kinds block, just only change the mould

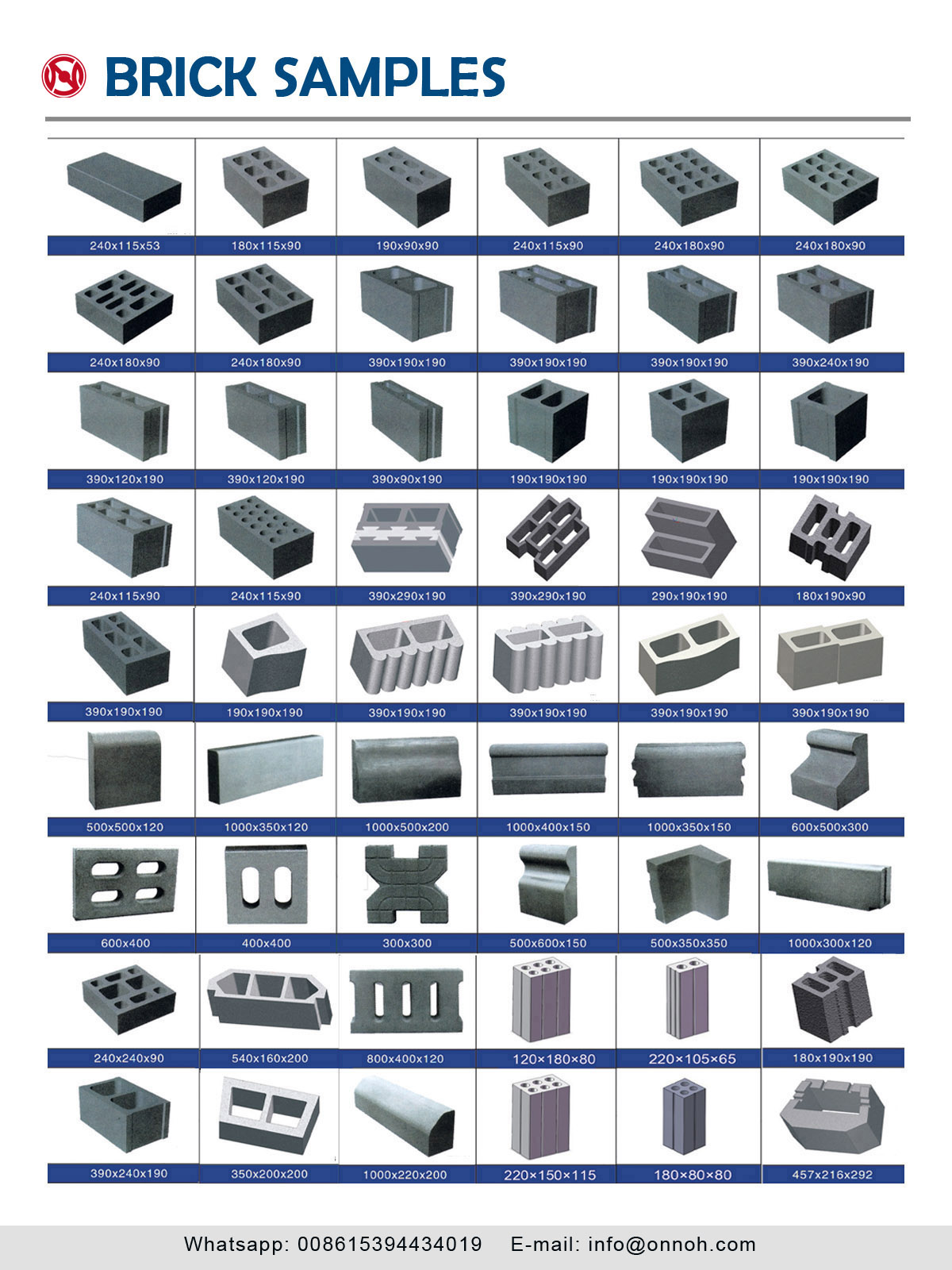

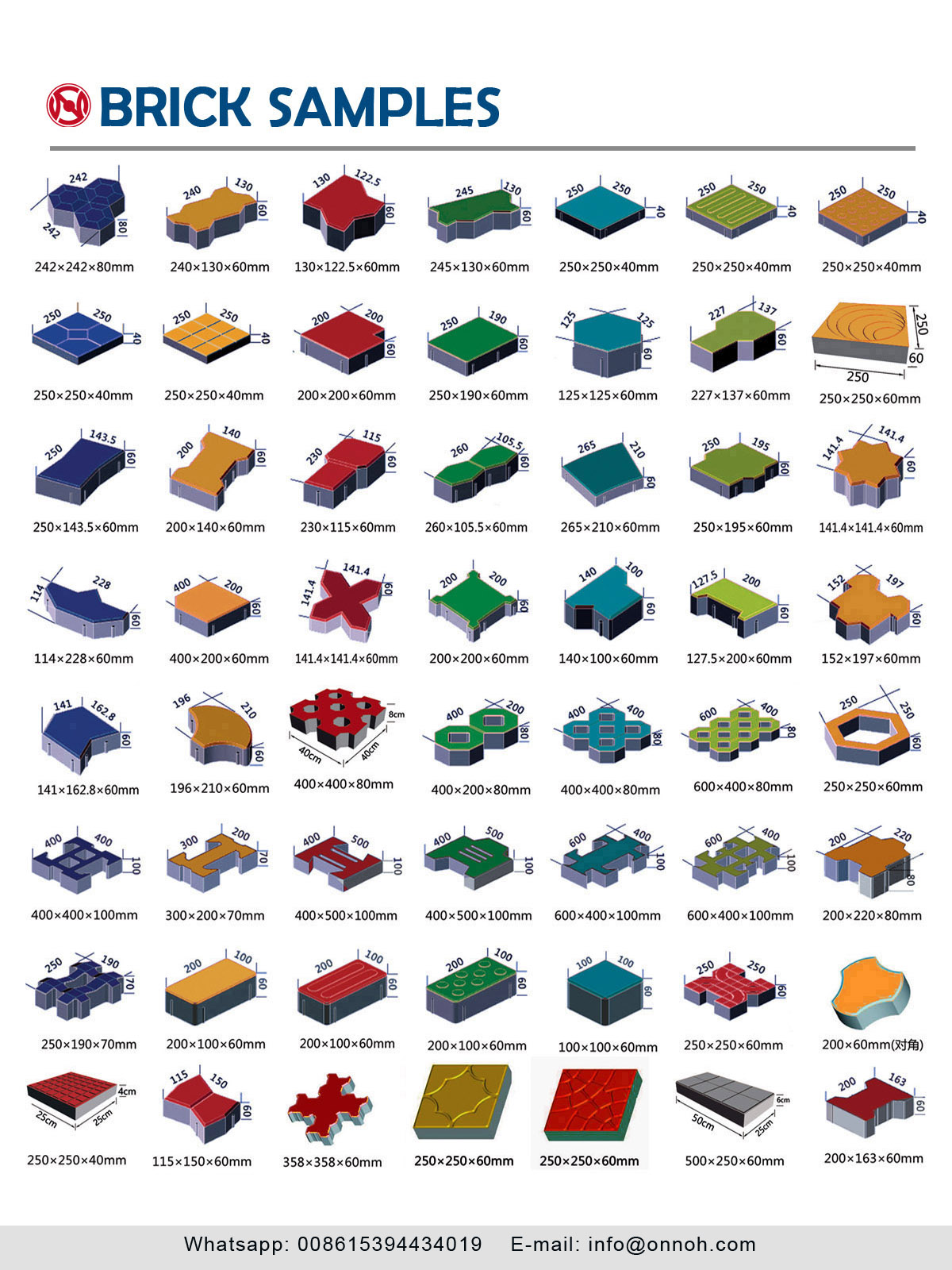

Block sample:

Change different moulds can make different blocks, we can design mould up to client required

Contact: Ms Kaner Tian

Phone: +86 15394434019

E-mail: info@onnoh.com

Add: Dongmen Industrial District,Fengzhou Town,Quanzhou ,Fujian .CHINA