![]() Deutsch

Deutsch

![]() Espanol

Espanol

![]() Francais

Francais

![]() Italiano

Italiano

![]() Portugues

Portugues

![]() Japanese

Japanese

![]() Korean

Korean

![]() Arabic

Arabic

![]() Russian

Russian

![]() Deutsch

Deutsch

![]() Espanol

Espanol

![]() Francais

Francais

![]() Italiano

Italiano

![]() Portugues

Portugues

![]() Japanese

Japanese

![]() Korean

Korean

![]() Arabic

Arabic

![]() Russian

Russian

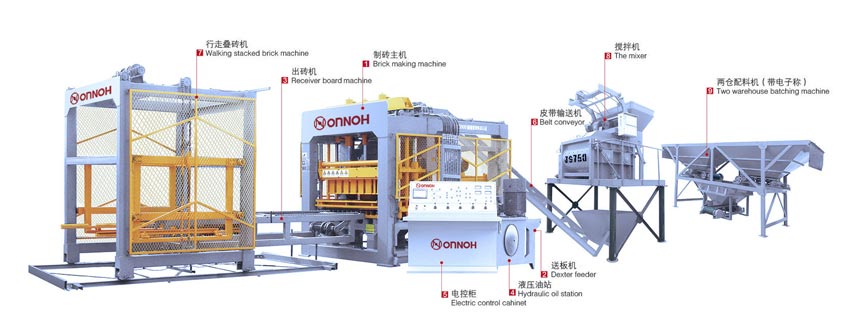

Onnoh qt12-15 automatic cement brick making machine electrical control system adopts PLC system, one machine with multiple functions: it can meet the production requirements of various specifications of concrete blocks, porous bricks, roadside bricks, slope protection bricks, river bricks, pavement bricks, square bricks and other blocks.

Qt12-15 automatic cement brick making machine is independently developed and produced by onnoh company. The equipment has compact structure, beautiful appearance, high durability, small error and high degree of automation. It imports computers, hydraulic parts, seals and other foreign common parts with high stability.

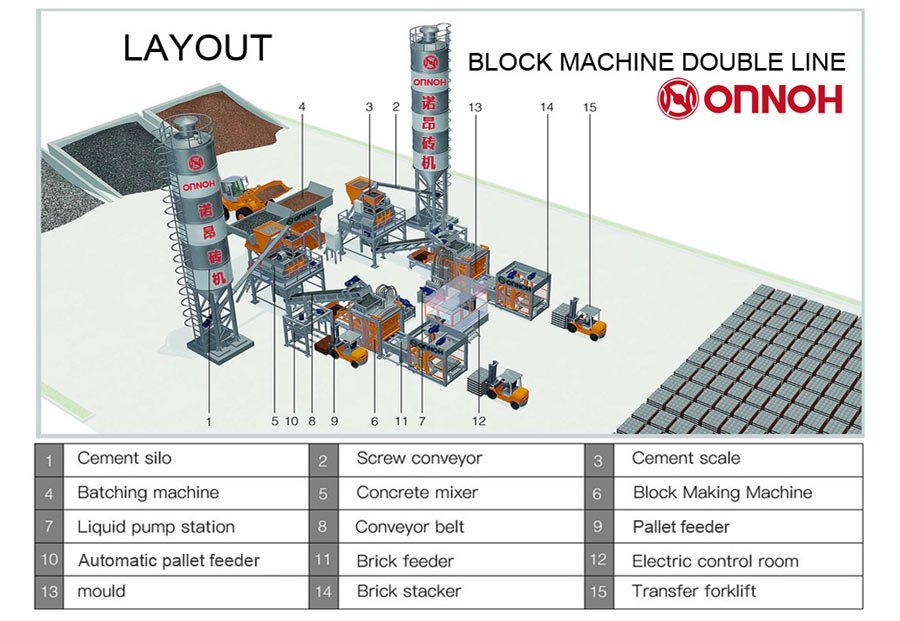

QT12-15 BLOCK BRICK MAKING MACHINE SIMPLE PRODUCE LINE:

The machine has multiple functions and can produce hollow bricks, color paving bricks, heat insulation bricks, grass planting bricks, etc. with high dimensional accuracy. The whole set of equipment is completely controlled by PLC, CNC computer, mechanical connection, hydraulic movement and advanced raw material input to ensure high product density.

QT12-15 Technical speciafications | |

Vibration trequency | 3800-4500(r/min) |

Total weight | 17(T) |

Machine Size | 11500*4550*2800(mm) |

Total power | 57.6(kw) |

Cycle time | 12-20(s) |

Rated pressure | 31.5MPa |

Vibration force | 150KN |

Pallet site | 1350*880*25(mm) |

Vibration type | Hydraulic vibration |

Stacking machine power | 3.7KW |

Item | size(mm)(L*W*H) | Quantity/ hour |

Concrete block | 390*190*190 | 1900-2100 |

Solid block | 240*115*53 | 9000-10800 |

Porous block | 240*115*90 | 4500-5400 |

1. The design is reasonable and the structure is compact. The body is made of strong section steel and special welding technology. Imported joint venture components are widely used to make the body more stable and reliable.

2. High efficiency and super strong excitation system design, using computer to control the frequency converter, so as to realize a variety of vibration frequencies and amplitudes, and greatly improve the compactness and production efficiency of products.

3. The whole machine adopts PLC and man-machine interface control system to realize random signal analysis and fault diagnosis, as well as the setting of various parameters required for forming, so as to make the machine achieve working effect.

4. Equipped with special hydraulic coder, it can easily realize large output, automatic production, save a lot of manpower, maintain the storage yard and put in working capital.

5. Semi closed forced spiral distribution system makes the distribution more uniform and fast.

6. The storage and distribution device adopts closed electric roller rotation, and the small hopper accumulator is strictly controlled to ensure that it can be used at any time, so as to prevent the early liquefaction of concrete by aftershocks and affect the distribution.

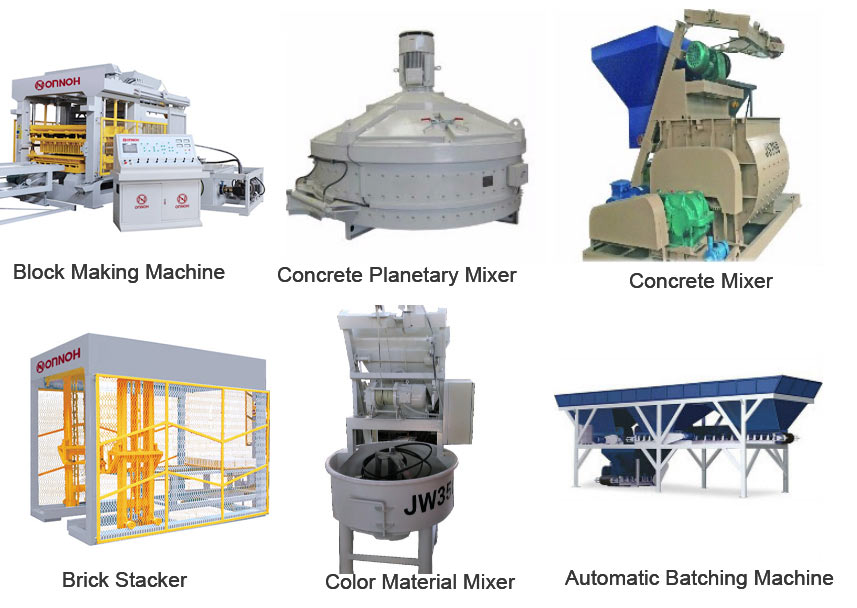

Fully automatic line as following:

1. Automatic weighing system

2. Twin shaft compulsory mixer

3. Mitsubishi PLC, Touch screen control unit

4. Hydraulic proportional relief valve automatically adjust the oil flow and speed

5. Heave duty frame of steel structure for heave working

6. Mould heat treatment with wire cutting

7. One production line can make all kinds block, just only change the mould

Block sample:

Change different moulds can make different blocks, we can design mould up to client required

Contact: Ms Kaner Tian

Phone: +86 15394434019

E-mail: info@onnoh.com

Add: Dongmen Industrial District,Fengzhou Town,Quanzhou ,Fujian .CHINA