![]() Deutsch

Deutsch

![]() Espanol

Espanol

![]() Francais

Francais

![]() Italiano

Italiano

![]() Portugues

Portugues

![]() Japanese

Japanese

![]() Korean

Korean

![]() Arabic

Arabic

![]() Russian

Russian

![]() Deutsch

Deutsch

![]() Espanol

Espanol

![]() Francais

Francais

![]() Italiano

Italiano

![]() Portugues

Portugues

![]() Japanese

Japanese

![]() Korean

Korean

![]() Arabic

Arabic

![]() Russian

Russian

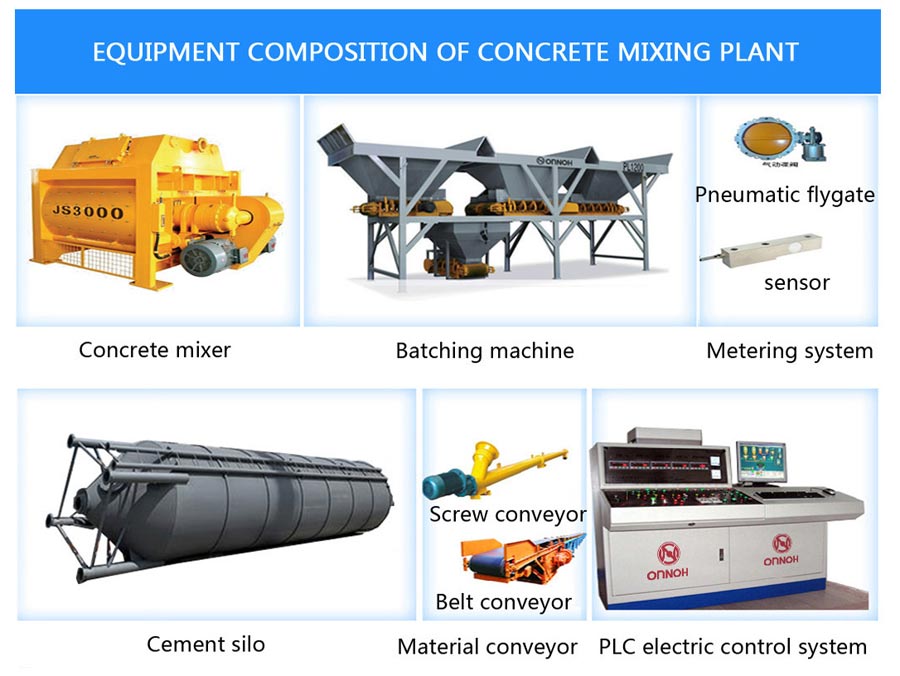

HZS series concrete mixing plant is composed of the mixing system, weighing system, conveying system, storage system and control system and other ancillary facilities. According to the difference of its configuration, applications and efficacy, etc

The feature of technology(Mixing plant)

1.Mixing system

A.Horizontal twin shaft mixer or PLANETARY mixer

B.Italian SICOMA MIXER or JS MIXER made by HXM company

C.Germany BHS,TEKA of mixer etc.

It is up to the budget of customer

2.Control system

A. Misubishi PLC. Self diagnosed for trouble shooting

B. Industry computer control plus printer, daily report, monthly report, yearly report

c.International electrical components:Omron, Schneider

D.Monitor system

3.Batching system

A.According to customer’s site. It has Under-ground batcher (concrete structure) and the ground batcher (steel structure)

B. It has Accumulative weighing system and individual weighing system

4.Belt system

A.Trough belt conveyor for the limited land

B.Long belt conveyor for the bigger land

5.Type of concrete mixing plant

A. Mobile batching plant can move to one place to one place

B.Modular batching plant can be easily tranfered to another place

C. Ready mixed batching plant only for the commercial concrete using

Modular concrete mixing plant -technical parameters | ||||||

Model | HZS50 | HZS75 | HZS100 | HZS150 | HZS200 | |

Productivity(m³/h) | 50 | 75 | 100 | 150 | 200 | |

Mixer | Model | JS1000 | JS1500 | JS2000 | JS3000 | JS4000 |

Mixing power(KW) | 2*22 | 2*30 | 2*37 | 2*55 | 2*75 | |

Output capacity(m³) | 1 | 1.5 | 2 | 3 | 4 | |

Aggregate size(mm) | ≤60 | ≤80 | ≤120 | ≤150 | ≤150 | |

Aggregate batcher | Hoppers capacity(m³) | 3*9 | 3*13 | 3*13 | 4*20 | 4*20 |

Hopper counts | 3 | 3 | 3 | 4 | 4 | |

Capacity of belt conveyor(t/h) | 200 | 300 | 400 | 500 | 600 | |

Weighing scope and precision | Aggregate(kg) | 2500±2% | 3500±2% | 4500±2% | 6500±2% | 9000±2% |

Cement(kg) | 600±1% | 900±1% | 1200±1% | 1800±1% | 2400±1% | |

Coal ash(kg) | 200±1% | 300±1% | 400±1% | 600±1% | 800±1% | |

Water(kg) | 300±1% | 400±1% | 600±1% | 800±1% | 1000±1% | |

Additive(kg) | 10±1% | 30±1% | 30±1% | 50±1% | 50±1% | |

Total power(kw) | 80 | 108 | 126 | 175 | 220 | |

Discharging height(m) | 3.8 | 3.8 | 3.8 | 3.8 | 3.8 | |

Contact: Ms Kaner Tian

Phone: +86 15394434019

E-mail: info@onnoh.com

Add: Dongmen Industrial District,Fengzhou Town,Quanzhou ,Fujian .CHINA