![]() Deutsch

Deutsch

![]() Espanol

Espanol

![]() Francais

Francais

![]() Italiano

Italiano

![]() Portugues

Portugues

![]() Japanese

Japanese

![]() Korean

Korean

![]() Arabic

Arabic

![]() Russian

Russian

![]() Deutsch

Deutsch

![]() Espanol

Espanol

![]() Francais

Francais

![]() Italiano

Italiano

![]() Portugues

Portugues

![]() Japanese

Japanese

![]() Korean

Korean

![]() Arabic

Arabic

![]() Russian

Russian

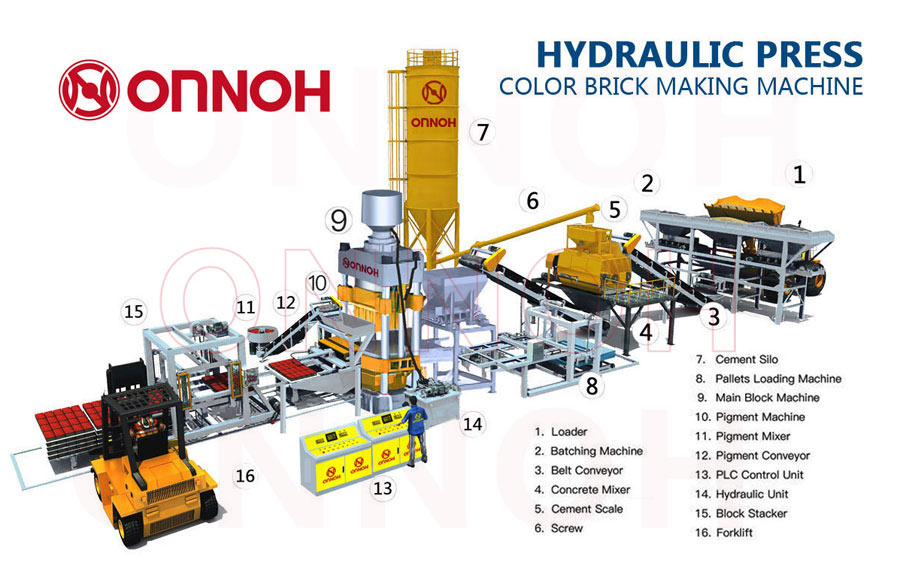

ONNOH DY800 hydraulic press brick making machine adopts PLC programmable to realize the integration of machine, electricity, gas and liquid. It is formed by pushing plate, cloth and strong pressure. The hydraulic extrusion process has the advantages of fast forming, low power consumption, uniform product structure, high strength, no pollution, low noise and other energy-saving effects.

DY800 hydraulic press color brick machine is mainly hydraulic, and the electric control system adopts PLC programmable to realize the integration of machine, electricity, gas and liquid. It is formed by pushing plate, cloth and strong pressure. The hydraulic extrusion process has the advantages of fast forming, low power consumption, uniform product structure, high strength, no pollution, low noise and other energy-saving effects.

Equipped with man-machine interface system, with automatic operation procedures such as automatic fault diagnosis, remote monitoring and production monitoring.

Main Technical Parameter | |

Model No. | DY800 |

Production capacity: | 36 pcs/mold (Standard solid brick: 238x113x48mm) |

24 pcs/mold (color paver: 200x100x60mm) | |

Forming period | Solid brick: 15-20s color brick: 20-25s |

Max pressure | 8000KN (800 T) |

Main power | 45 KW |

Pump max pressure | 31.5 Mpa |

Machine size | 7500x4000x4200 mm |

Pallet size | 950x850x20 mm |

Machine weight | 18000 kg (18 T) |

Mixing power | 4.5 KW |

Vibration power | 2×5.5 KW |

Hydraulic system | YUKEN Valve |

Cylinder diameter | Φ630mm inner |

PLC Control system | Siemens etc. |

Contact: Ms Kaner Tian

Phone: +86 15394434019

E-mail: info@onnoh.com

Add: Dongmen Industrial District,Fengzhou Town,Quanzhou ,Fujian .CHINA